Franke 리니어 시스템 기본 원리

독특한 역동성

독특한 개별성

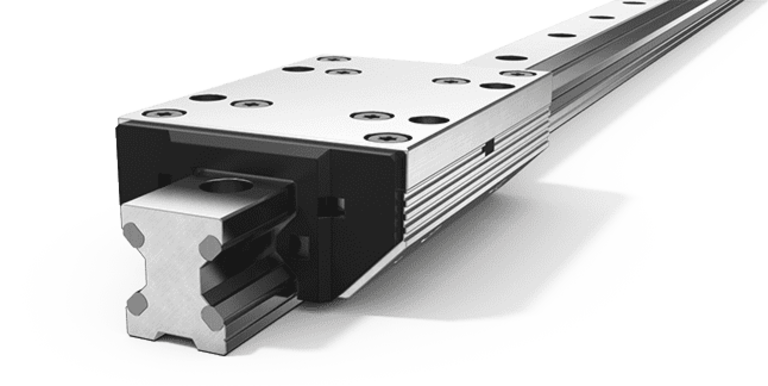

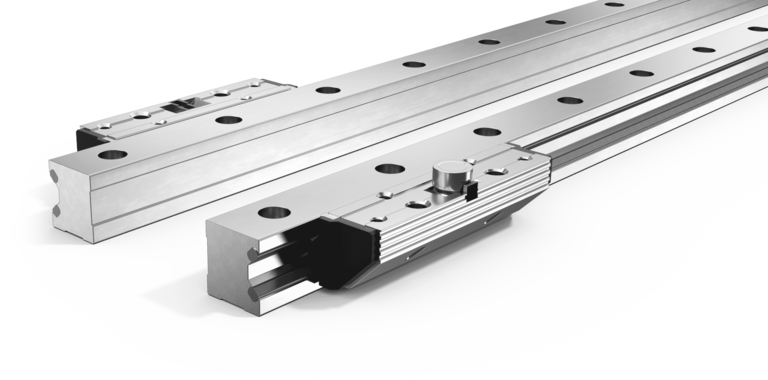

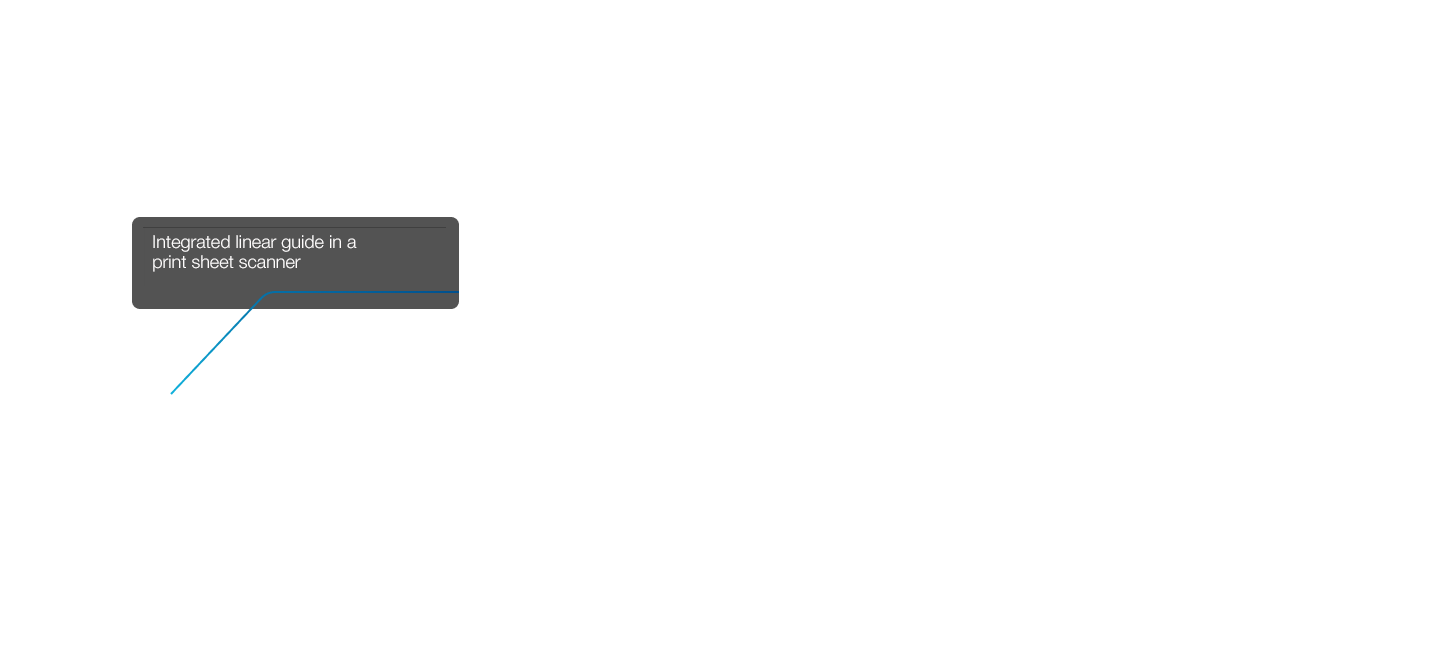

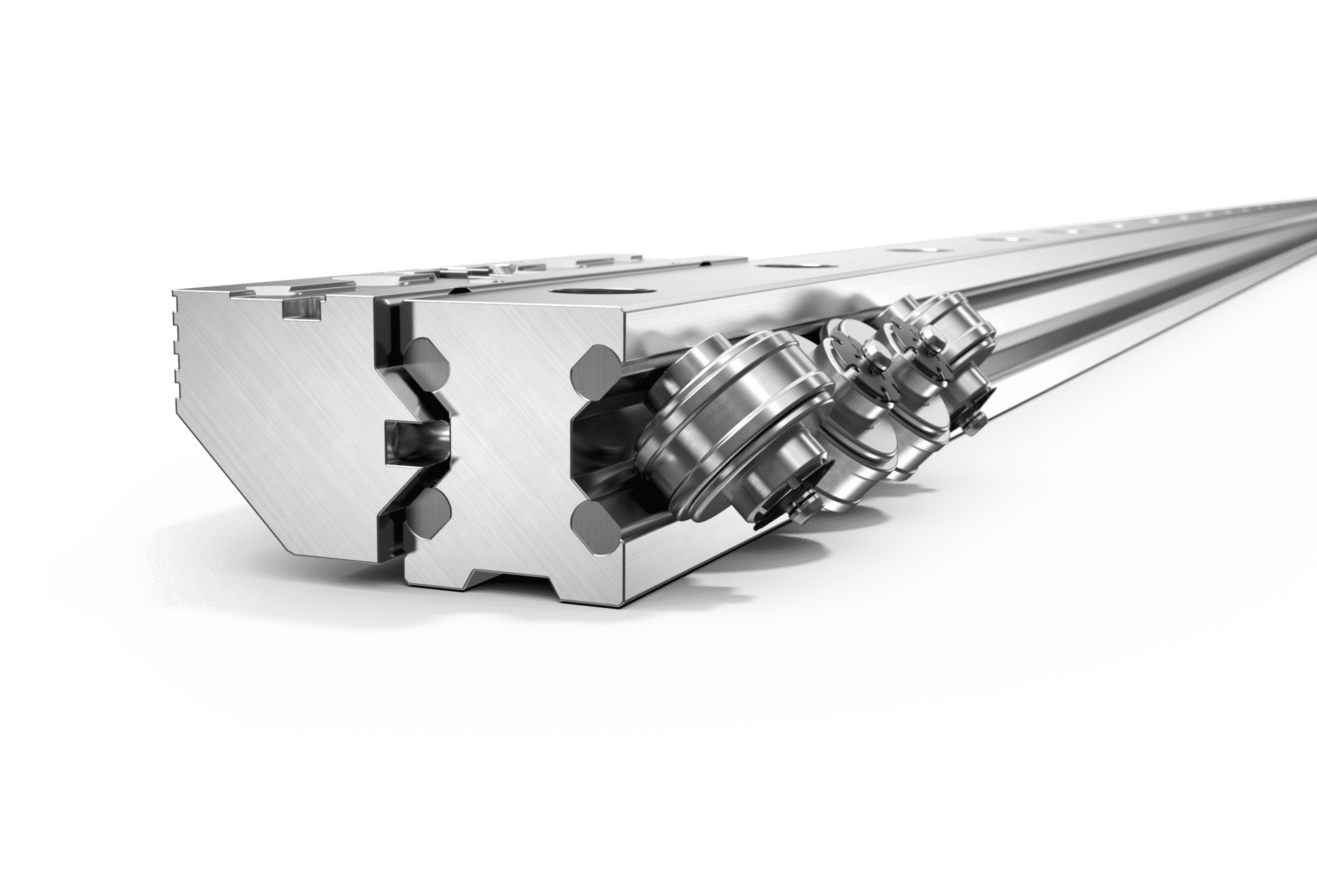

프랑케 리니어 시스템은 와이어 레이스 베어링의 기발한 원리를 선형 운동으로 전달합니다.

삽입된 레이스웨이는 모든 방향의 하중을 보장합니다. 따라서 나머지 구조는 가벼운 알루미늄으로 제작할 수 있습니다. 대형 가이드 롤러는 전체 서비스 수명 동안 유지보수 없이 원활하게 작동합니다.

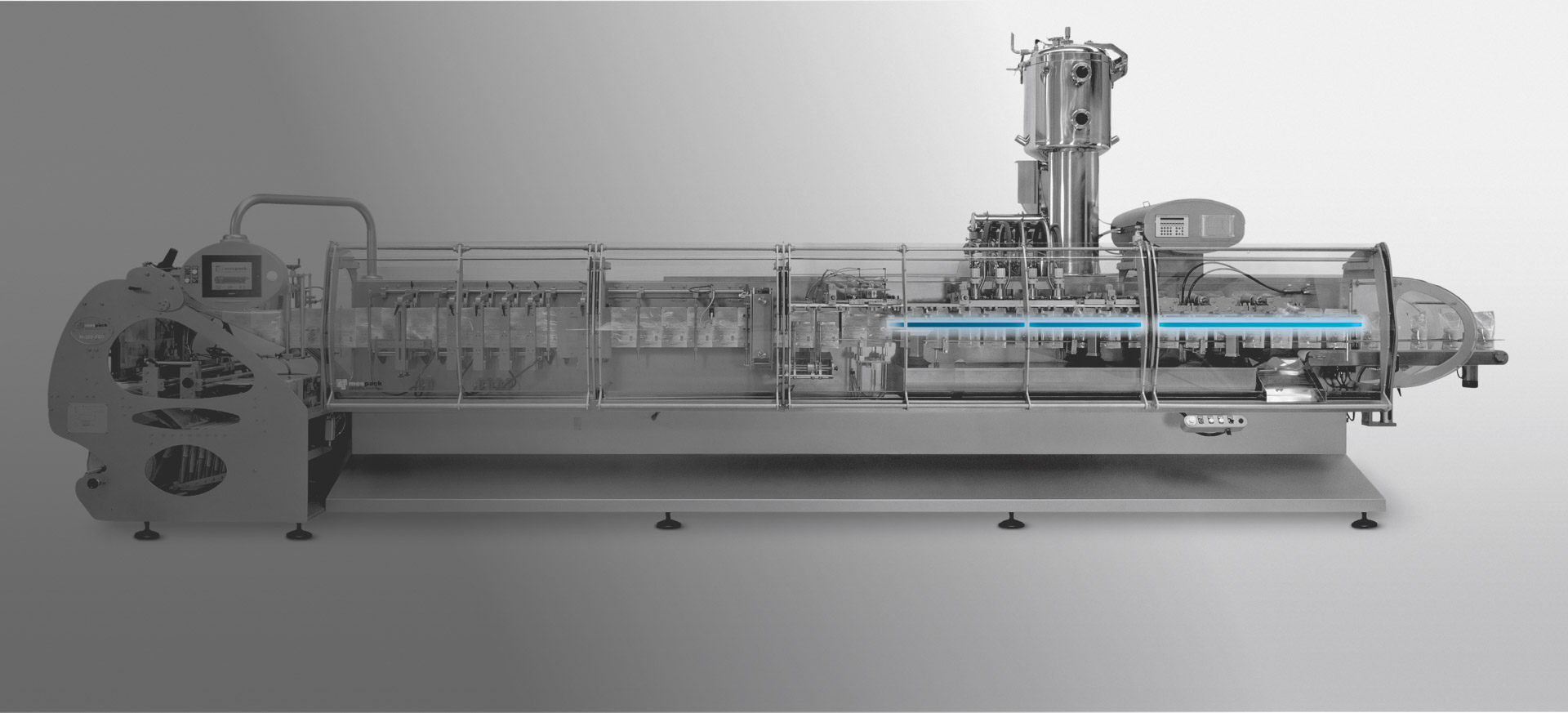

모듈식 설계 덕분에 프랑케 선형 시스템은 요구 사항에 개별적으로 적용할 수 있습니다.

당신의 솔루션 – 신속하게 제공됩니다

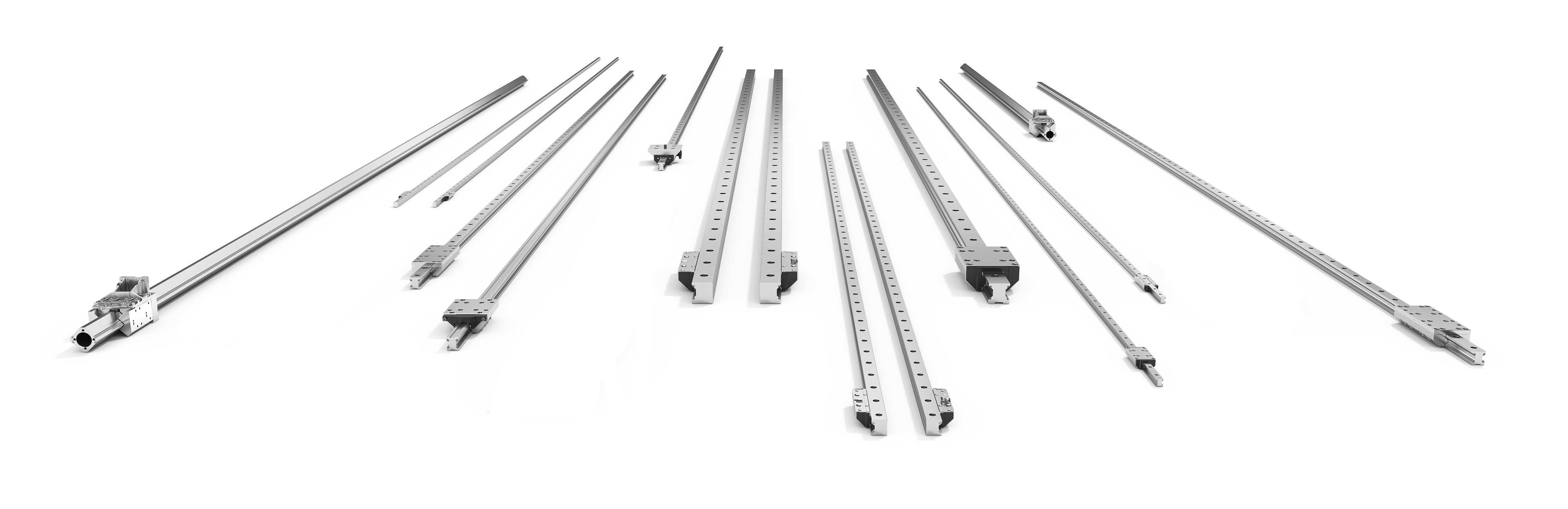

다양한 표준 제품군에서 이미 귀하의 어플리케이션에 적합한 선형 시스템을 찾으실 수 있을 것입니다. 추가 요구사항도 개별적으로 충족 가능하니 언제든 문의해 주십시오.

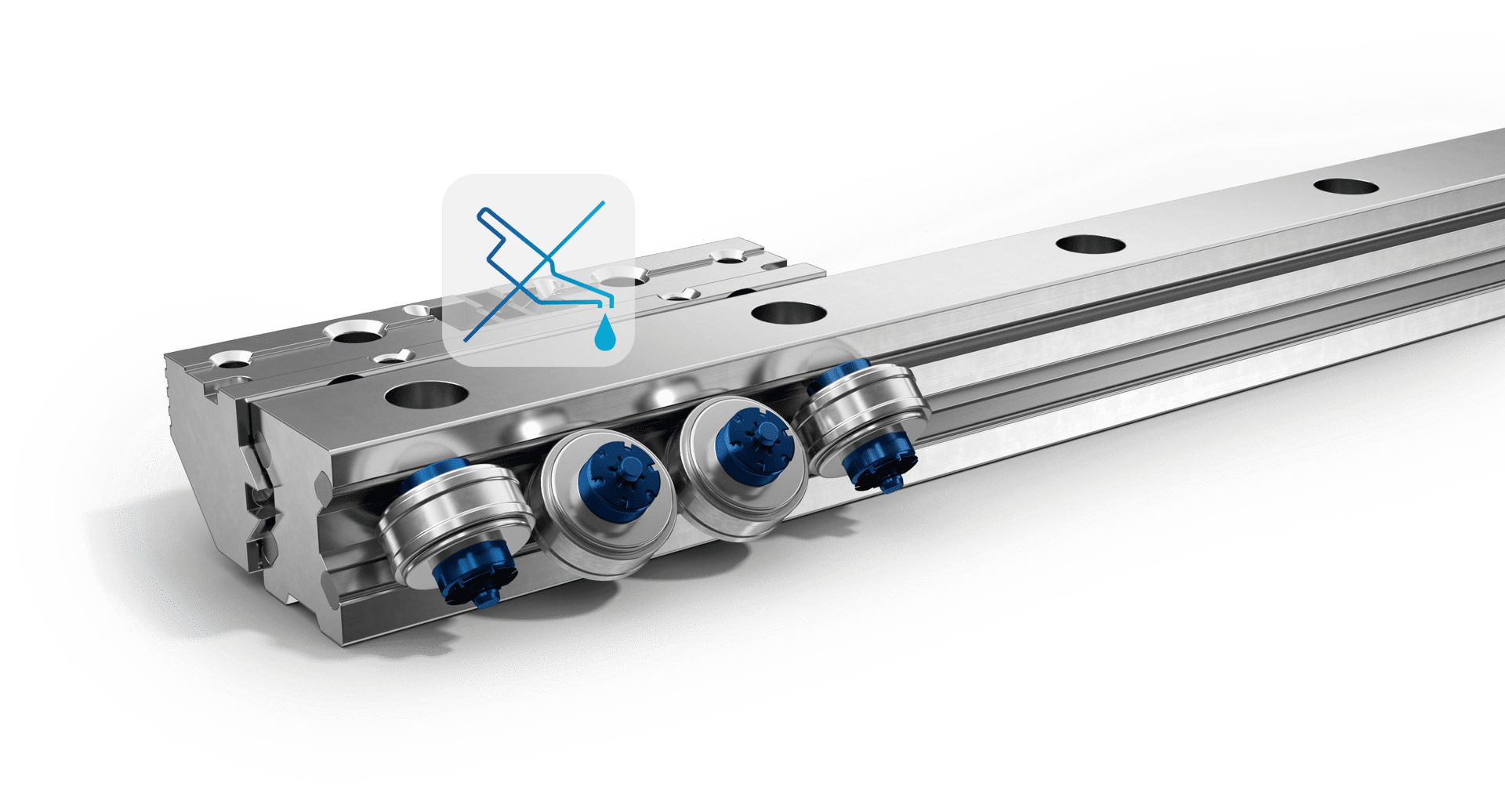

Maintenance-free - carefree

The needle or ball bearings used in the rollers are lubricated for life. This means that no maintenance is required over the long life of a Franke linear guide. For applications in the food industry we also offer lubricant-free roller bearings.

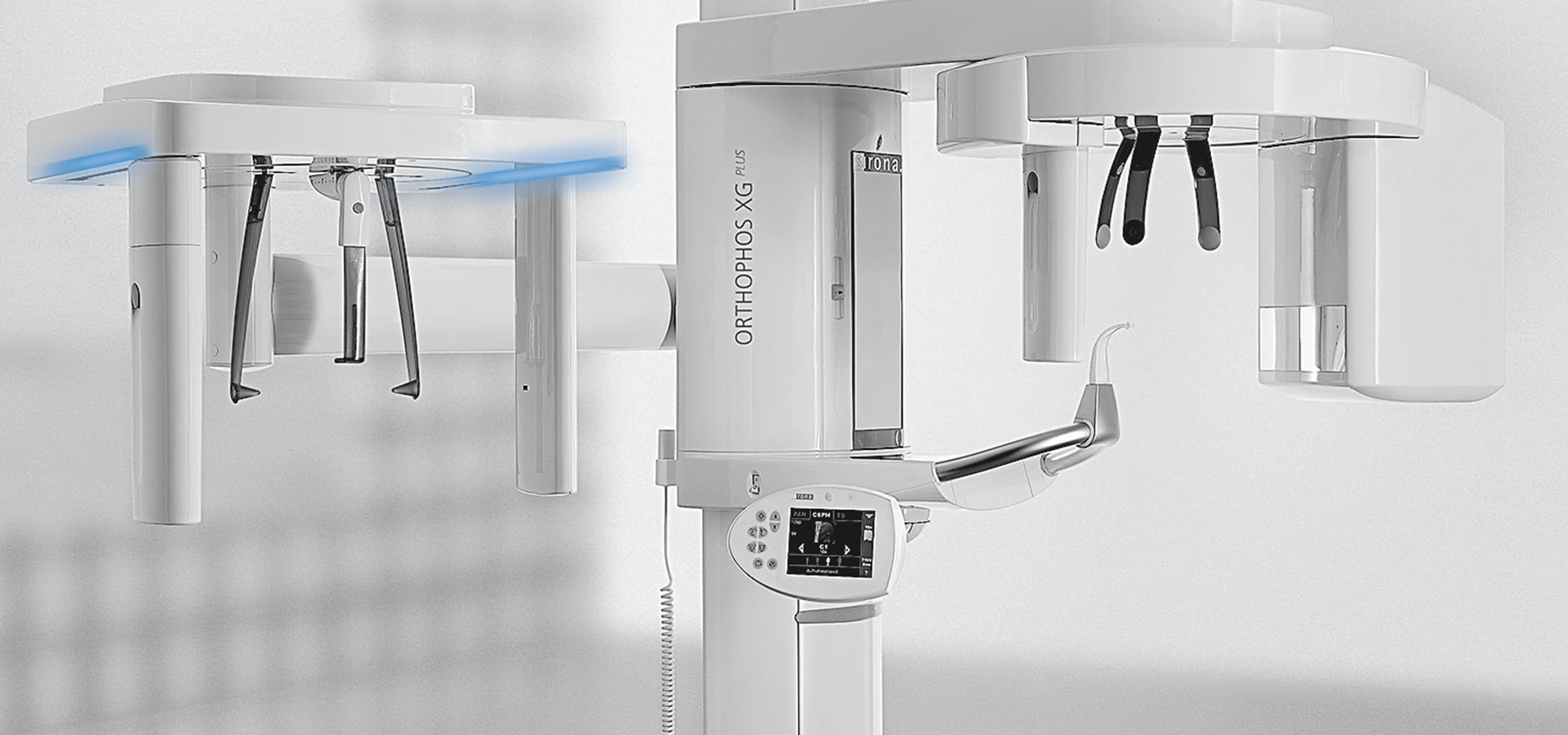

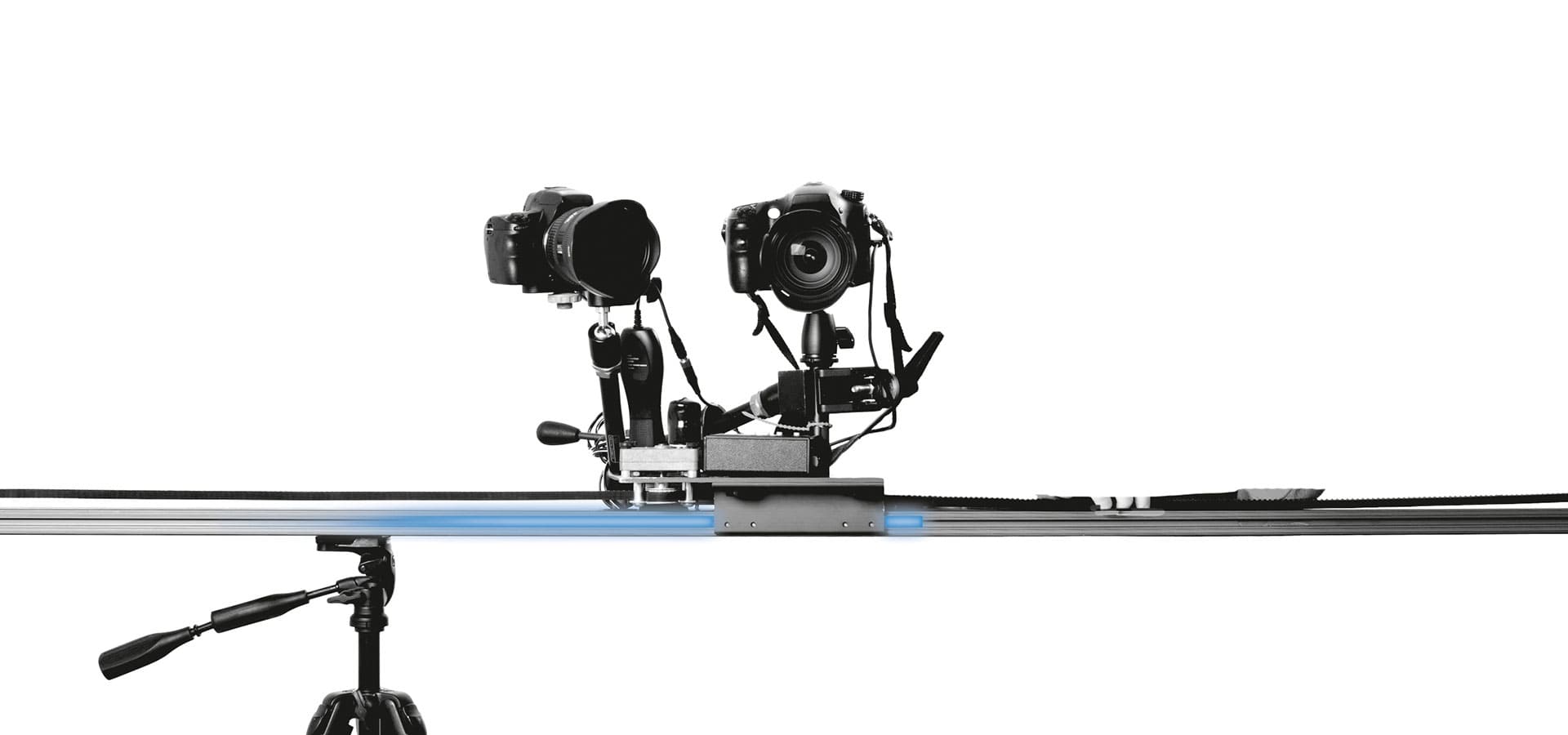

Accelerate more easily

Franke linear systems are the first choice when highest dynamics are required. The large rollers are mounted very smoothly. They run with low friction and precisely guided on the inserted tough and hard steel wires. Because almost exclusively light aluminum is used for the entire construction, the moving mass is low. The result: Highest dynamics and energy efficiency.

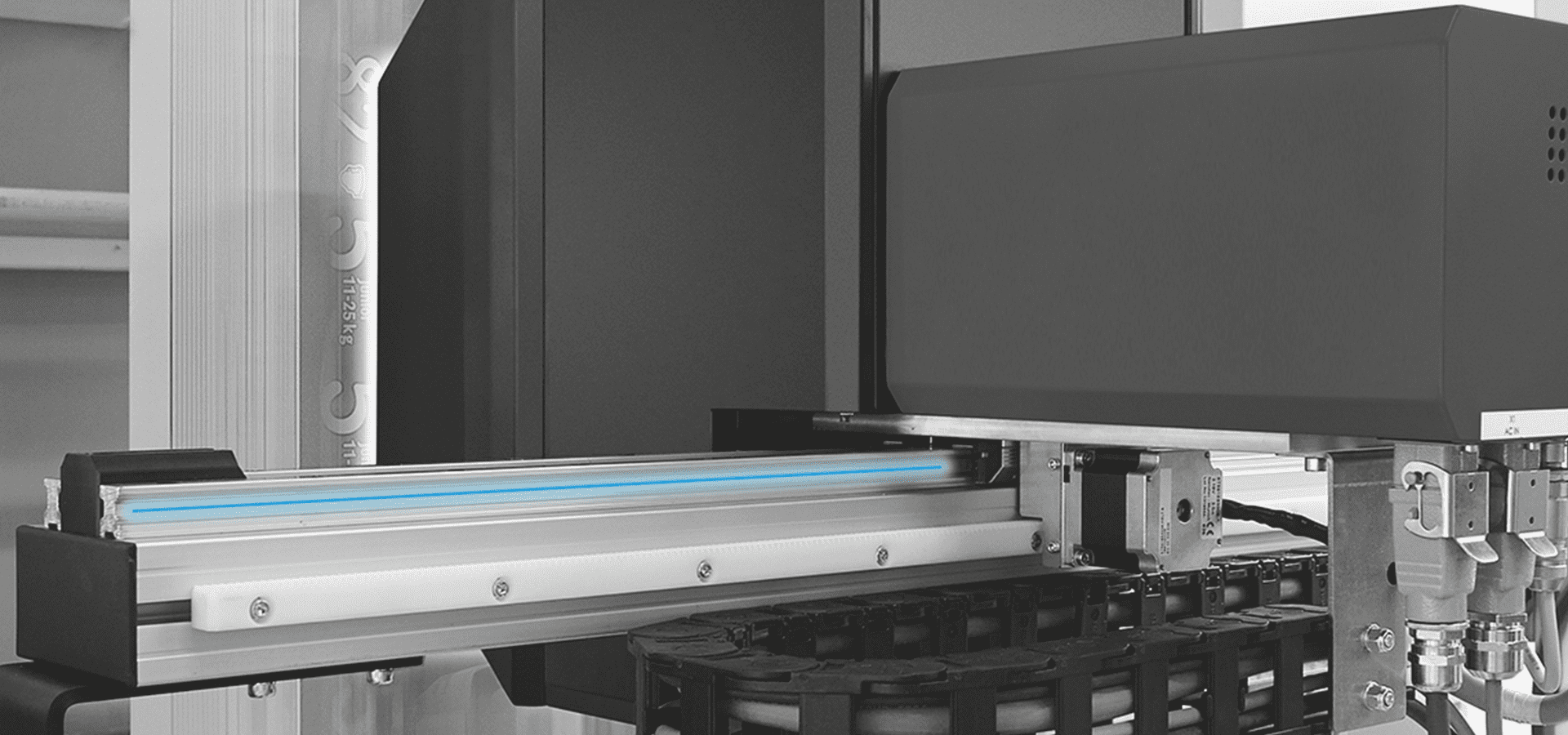

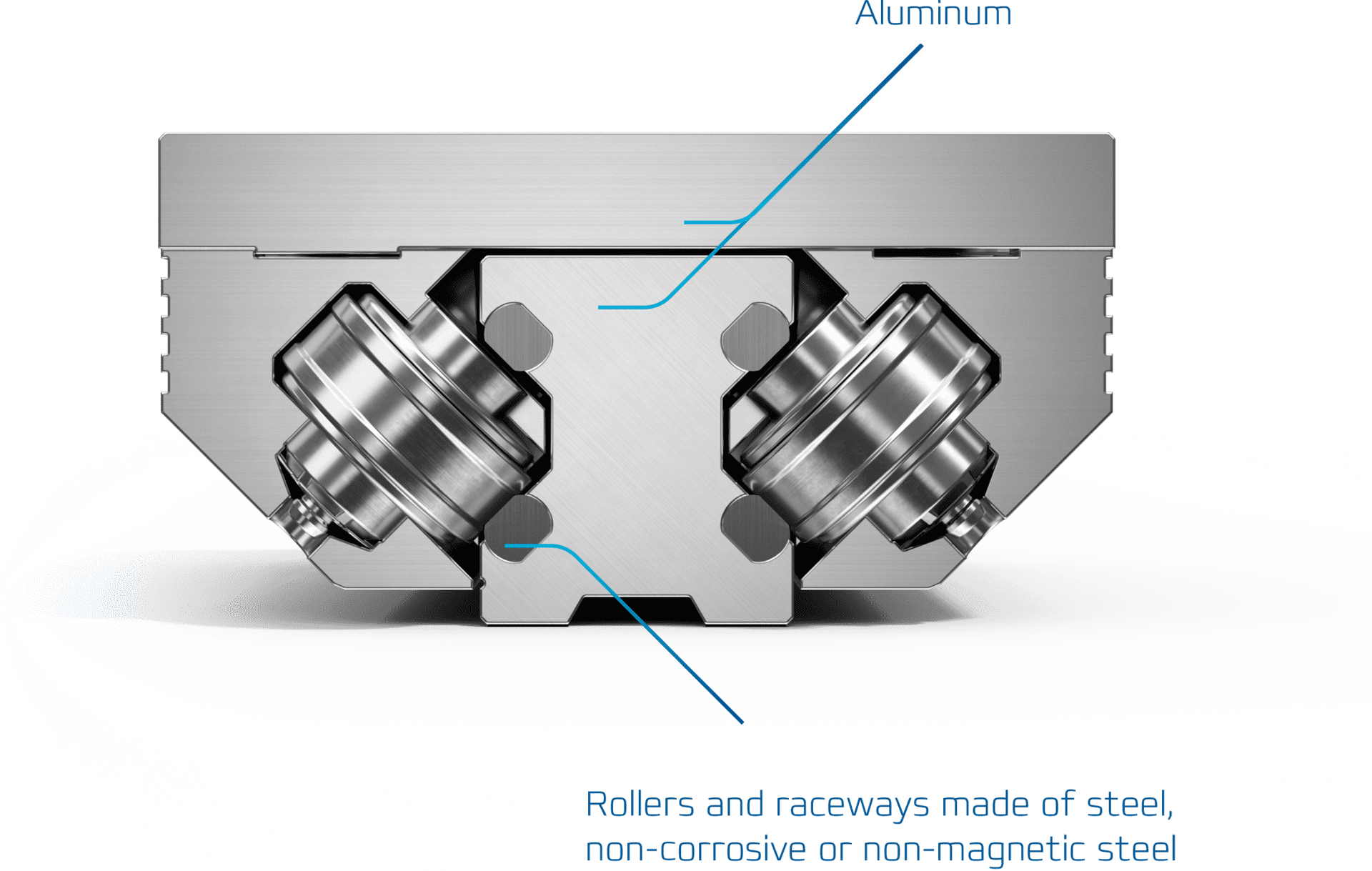

Designing homogeneously with aluminum

The main components of Franke linear systems - rails and cassettes - are made of aluminium. Franke linear systems are ideally suited for constructions made of aluminum, because the homogeneous materiality excludes temperature-related distortions.

The quieter the better

Where Franke linear systems are used, you hear almost nothing from them. Only a quiet, homogeneous noise can be heard. This makes them ideally suited for noise sensitive applications. Furthermore, the whisper-quiet operation is an audible quality feature.

Highly accurate and durable

Franke's core competence lies in the high-precision manufacture and machining of wire raceways. The pursuit of precision determines every single step of our work. The result is bearing solutions with outstanding accuracy values and an excellent service life.

Patented guidance

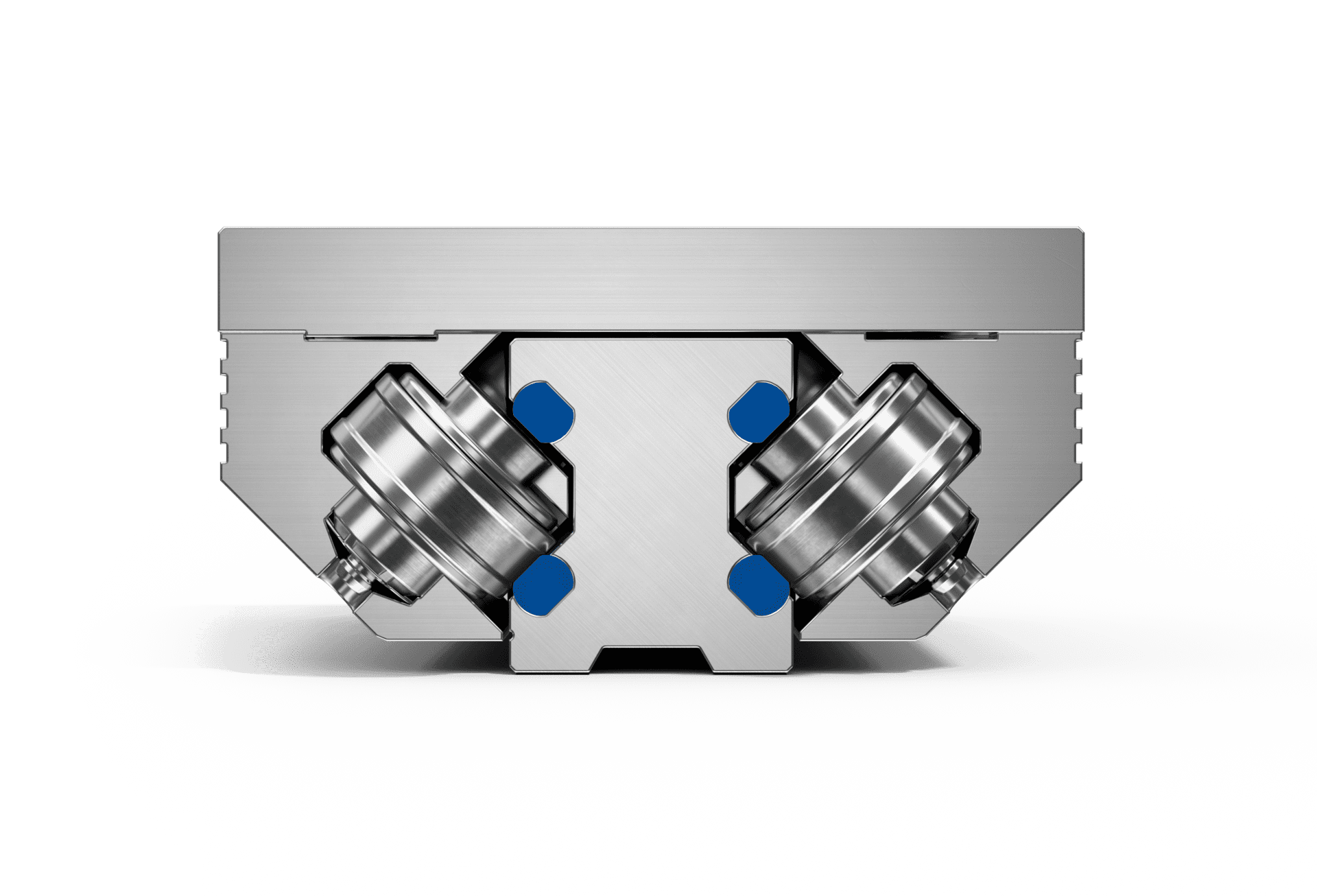

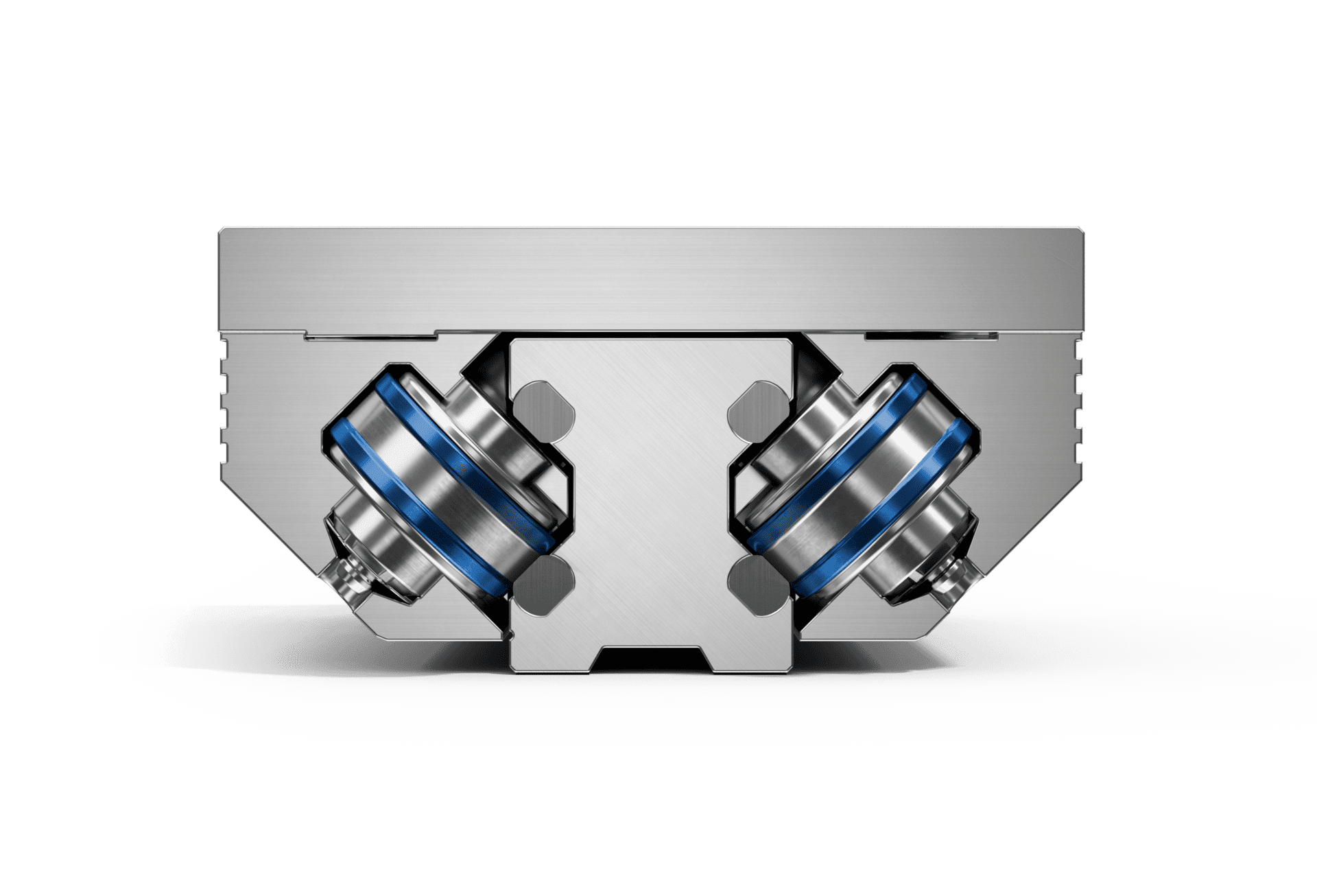

Franke track rollers have a groove adapted to the wire tracks. This patented type of guidance prevents the rollers from sliding on their bearing pins and rubbing against the housing. The advantage: a lower friction, more controlled movement.

Loadable on all sides

The rollers are arranged crosswise and run on one of the four wires each. In this way, forces are absorbed on all sides and the installation position can be freely determined. Depending on the profile rail used, the bearing can be designed with an external guide in an O arrangement (figure right) or with an internal guide in an X arrangement.

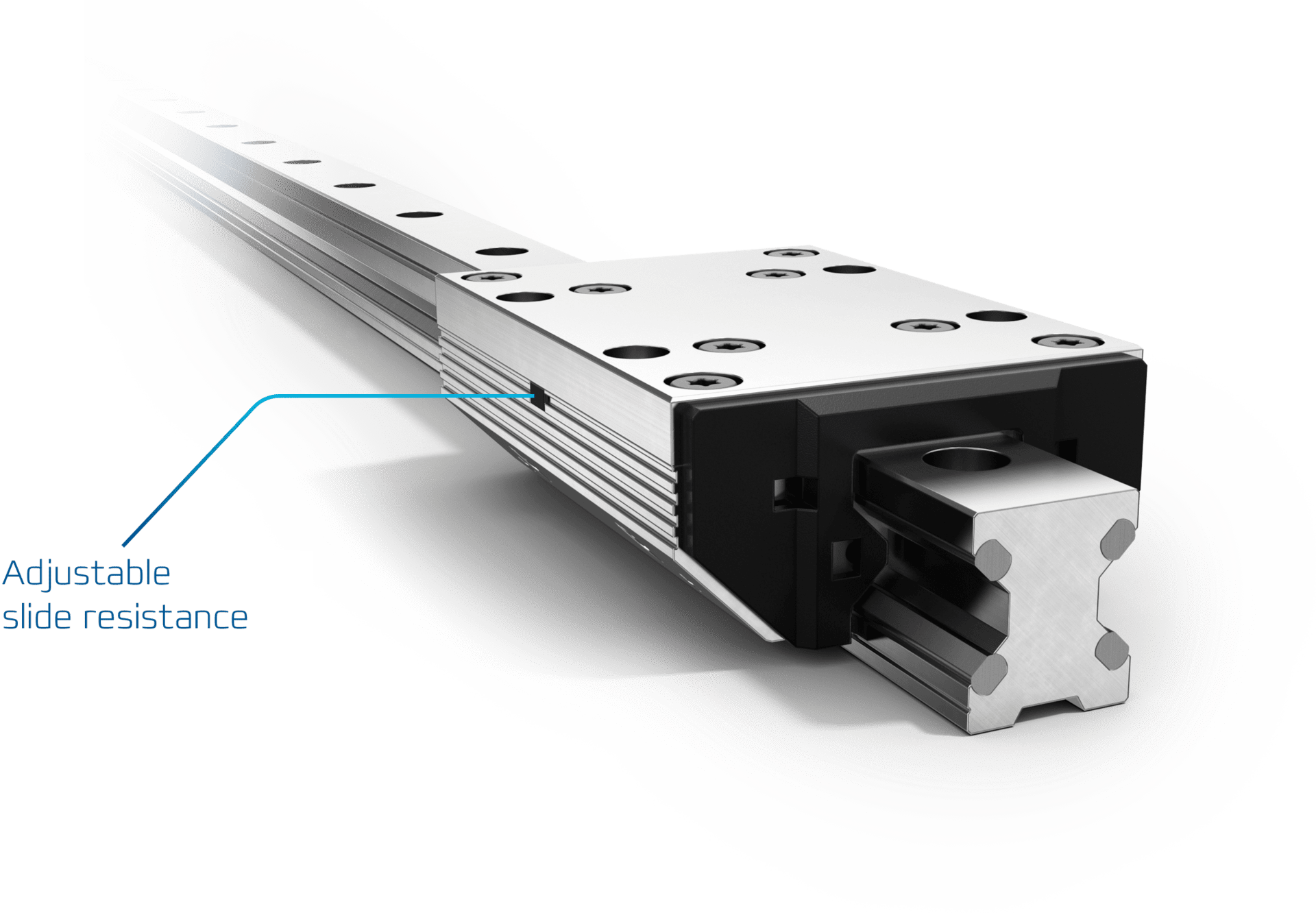

Always the right sliding resistance

The sliding resistance of Franke linear guides can be adjusted to the application at any time using an adjusting screw. Very fine adjustments are possible. This allows the system to be adapted to the load - in the direction of smooth running or in the direction of stiffness and vibration resistance.

The best system for you

Only your application and your construction decide which linear system is the best for you. The Franke modular system makes it possible to put together or design an ideal system for you. X linear system projects in over 45 years prove the efficiency of Franke linear systems.

Your contact

상세한 상담은 모든 성공적인 프로젝트의 기반입니다.

기꺼이 직접 상담해 드리겠습니다.

Forrest Kim / 김현철

President Franke Korea

Phone: 032 424 7939

Mobile: 010 2591 1425